Hdpe Hank

Hdpe Hank Specification

- Density

- 0.95 Gram per cubic centimeter(g/cm3)

- Construction

- Monofilament multi-strand twisted

- No Of Ply

- 3

- Tensile Strength

- High

- Capacity

- Depends on application

- Material

- HDPE (High-Density Polyethylene)

- Type

- Hank

- Texture

- Smooth

- Style

- Twisted

- Application

- Fishing nets, twines, rope making, packaging, household and industrial uses

- Diameter

- 1 mm to 8 mm

- Thickness

- Standard

- Length

- Standard/As required

- Characteristics

- High strength, UV resistant, lightweight, durable, flexible

- Ply

- 3 Ply

- Color

- White

- Size/Dimensions

- Customizable as per requirement

- Shape

- Bundle/Hank

- Knot Strength

- Retains up to 85% tensile strength

- Shrinkage

- Low

- Packaging

- Bundled in coils or hanks

- Abrasion Resistance

- High

- Water Absorption

- Negligible

- Elongation At Break

- 12-15%

- Melting Point

- 130°C to 135°C

- Finish

- Glossy

Hdpe Hank Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T)

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Hdpe Hank

Backed by our diligent employees and rich industrial experience, we have managed to become one of the leading manufacturers and suppliers of HDPE Hank. We make these hanks accessible in different colors and bundle sizes. Moreover, our provided assortment is braided with high precision utilizing excellent quality high density polyethylene by adroit experts. These are extensively used for packaging, handicraft designing as well as binding applications. Also, Our offered range of HDPE Hank is demanded for their excellent finish and light weight.

Features:

-

Excellent strength

-

Controlled elongation

-

Resistant to chemicals and unaffected by weather

Exceptional Strength and Durability

Manufactured with high-density polyethylene, the HDPE Hank exhibits superior tensile strength, retaining up to 85% even at knots, making it reliable for demanding tasks. Its high abrasion resistance and low shrinkage further enhance longevity, ensuring consistent performance whether used outdoors or in industrial settings.

Versatile and Customizable Applications

Available in various diameters and customizable lengths, HDPE Hanks are suitable for fishing nets, household uses, packaging, rope making, and industrial needs. The 3-ply, twisted monofilament construction strikes a balance between flexibility and robustness, adapting seamlessly to diverse requirements.

Convenient Packaging and Smooth Finish

Bundled as coils or hanks and finished with a smooth, glossy texture, these hanks are easy to handle, store, and transport. Their lightweight nature and white color provide further versatility and aesthetic appeal, while the consistent quality assures satisfaction for every application.

FAQs of Hdpe Hank:

Q: How does the HDPE Hank retain strength at knots during use?

A: The HDPE Hank is designed to retain up to 85% of its original tensile strength even when knotted, thanks to its monofilament multi-strand twisted construction. This makes it highly reliable for applications like rope making and fishing nets, where knot strength is critical.Q: What makes the HDPE Hank suitable for both industrial and household applications?

A: The combination of high strength, negligible water absorption, UV resistance, and flexibility makes the HDPE Hank ideal for a wide range of uses, including packaging, rope making, fishing nets, and general household tasks. Its customizable sizes further expand its application potential.Q: When should I use a 3-ply HDPE Hank instead of single-ply alternatives?

A: A 3-ply HDPE Hank is recommended when you require enhanced strength, durability, and abrasion resistance. Its multi-strand construction provides added resilience, especially beneficial for heavy-duty or outdoor uses where more robust material performance is essential.Q: Where are HDPE Hanks typically manufactured and supplied from?

A: In India, HDPE Hanks are widely manufactured, supplied, and traded by specialized producers. These manufacturers ensure quality standards and provide customization to suit different industry needs and customer requirements.Q: What is the process behind producing HDPE Hanks with low water absorption and high durability?

A: HDPE Hanks are made using high-density polyethylene fibers, twisted into multi-strand monofilament yarns. This process ensures negligible water absorption, high UV resistance, and remarkable durability, resulting in hanks that maintain performance in challenging environments.Q: How should I store and handle bundled HDPE Hanks?

A: HDPE Hanks, supplied in coils or hanks with a glossy smooth finish, should be stored in a dry, cool area away from direct sunlight to preserve their UV resistance and flexibility. Their bundled design allows for easy handling and efficient storage.Q: What are the benefits of choosing HDPE Hanks for packaging or rope making?

A: HDPE Hanks offer significant advantages, including high strength, lightweight structure, low shrinkage, and excellent abrasion resistance. These features reduce breakage risks and ensure long-term performance, making them a cost-effective and dependable choice for packaging or rope making.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Fishing Twine Hank Category

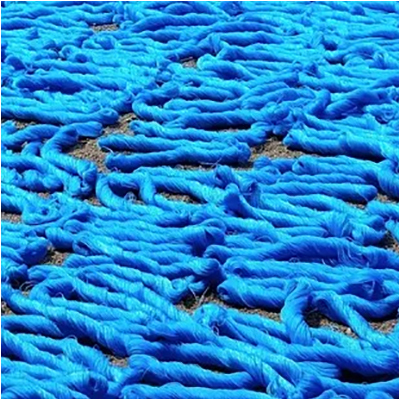

Blue Fishing Hank

Price 120 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Type : Twine

Texture : Twisted

Application : Construction, Fishing , Agriculture, Safety net

Style : Plain

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry