Mono Filament Cloths

Price 120 INR/ Kilograms

Mono Filament Cloths Specification

- Shrinkage

- Negligible

- Fabric Capacity

- Good permeability, high filtration efficiency

- Feature

- Other

- Fabric Type

- Mono filament cloth

- Style

- Industrial filtration fabric

- Color

- White

- Length

- Custom as per requirement Meter (m)

- Yarn Type

- Monofilament

- Width

- 40 to 150 inch (approx.) Meter (m)

- Material

- Polyester monofilament

- Texture

- Smooth and fine

- Pattern

- Plain weave

- Technics

- Woven

- Weight

- 35-200 GSM (grams per square meter) GSM (gm/2)

- Density

- Gram per cubic centimeter(g/cm3)

- Yarn Count

- Varies as per mesh size

Mono Filament Cloths Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Payment Terms

- Telegraphic Transfer (T/T)

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Mono Filament Cloths

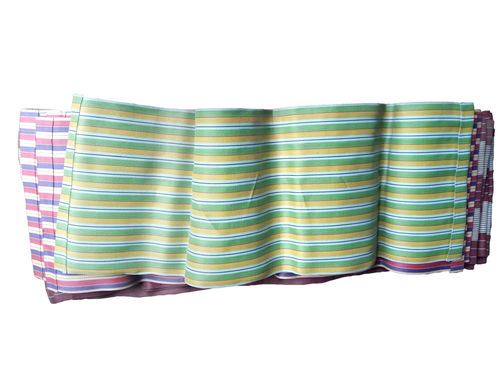

With an aim to serve our clients and establish ourselves as a brand, we are indulged in manufacturing and supplying excellent quality Mono Filament Clothes. These are most suitable for making wedding veils and bridal gowns. Apart from that, these clothes can also be used for fabricating scarves, curtains, gift bags and decorative items. It is made up of very light weight material which gives the garment a lacy finishing and floating look. Mono Filament Clothes are made available to the clients in different lengths and textures to choose from.

Features:

-

Long lasting shine

-

Very lightweight and easy to clean

-

Floating look

Versatile Mesh Sizes for Multiple Applications

Select from mesh sizes as fine as 10 mesh up to 500 mesh, catering to diverse needs such as filtration, sieving, separation, and screen printing. This flexibility allows industries to achieve precision in their processes while ensuring effective performance.

Superior Material and Surface Quality

Constructed from premium polyester monofilament, these fabrics boast a smooth, glossy, and non-absorbent finish. The result is minimal moisture absorption, enhanced chemical resistance, and consistent filtration capabilitieseven under challenging conditions.

Customizable Dimensions and Reliable Packaging

Each cloth can be tailored in width (40-150 inches) and length to meet project requirements. Secure packing in rolls or cut pieces with poly wrap or cartons protects the fabric during transit and storage, ensuring a pristine product upon delivery.

FAQs of Mono Filament Cloths:

Q: How are mono filament cloths typically used in filtration and sieving processes?

A: Mono filament cloths are ideal for both filtration and sieving due to their uniform mesh structure and high permeability. They efficiently separate particles of varying sizes, ensuring high filtration efficiency in both industrial and laboratory environments.Q: What benefits does the polyester monofilament material provide?

A: Polyester monofilament offers excellent chemical resistance, high tensile strength, and dimensional stability. Its glossy surface prevents moisture absorption and contamination, making it suitable for demanding applications and repeated use.Q: When should I choose a specific mesh size for my application?

A: The selection of mesh size depends on the particle size you wish to separate or filter. Finer meshes (higher mesh numbers) are suitable for small particles, while coarser meshes are effective for larger particles. Customization allows optimal performance tailored to your process.Q: Where can the mono filament cloth be applied beyond filtration?

A: In addition to filtration and sieving, mono filament cloth is commonly used for separation processes and as screens in the screen printing industry, thanks to its stability, smoothness, and robust performance under various conditions.Q: What is the typical process for ordering and packaging these cloths?

A: Cloths can be ordered in custom sizes and are packaged as rolls or cut pieces, with secure poly wrapping or cartons to preserve fabric quality during shipping. Edge finishing can be specified as heat set or laser cut based on your handling needs.Q: How does the fabrics temperature resistance enhance its usage?

A: With the ability to withstand temperatures up to 150C, these fabrics perform reliably even in environments where heat exposure is frequent, maintaining their filtration properties and structural integrity.Q: What are the major advantages of the heat set or laser cut edge finishing?

A: Heat set and laser cut edges help prevent fraying and ensure clean, stable borders. This method improves handling, longevity, and the overall performance of the cloth during installation and repeated use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mono Filament Cloth Category

Mono Cloth

Price Range 140.00 - 160.00 INR

Minimum Order Quantity : 50 Kilograms

Width : 3660 inches

Technics : Woven

Length : Customizable

Pattern : Plain

Monofilament Fabric

Price Range 140.00 - 160.00 INR

Minimum Order Quantity : 50 Kilograms

Width : 127 cm to 365 cm

Technics : Woven

Length : Custom as per requirement

Pattern : Plain

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry